Nobis Case Study

Nobis Rehabilitation Partners operates orthopedic recovery centers in cities throughout the nation, offering personalized in-patient treatment for patients who have experienced life-altering accidents or diseases. While the company’s treatment options vary from site to site, all of its facilities require high-performing HVAC equipment to maintain healthcare-code-compliant conditions for patients.

Previous Situation

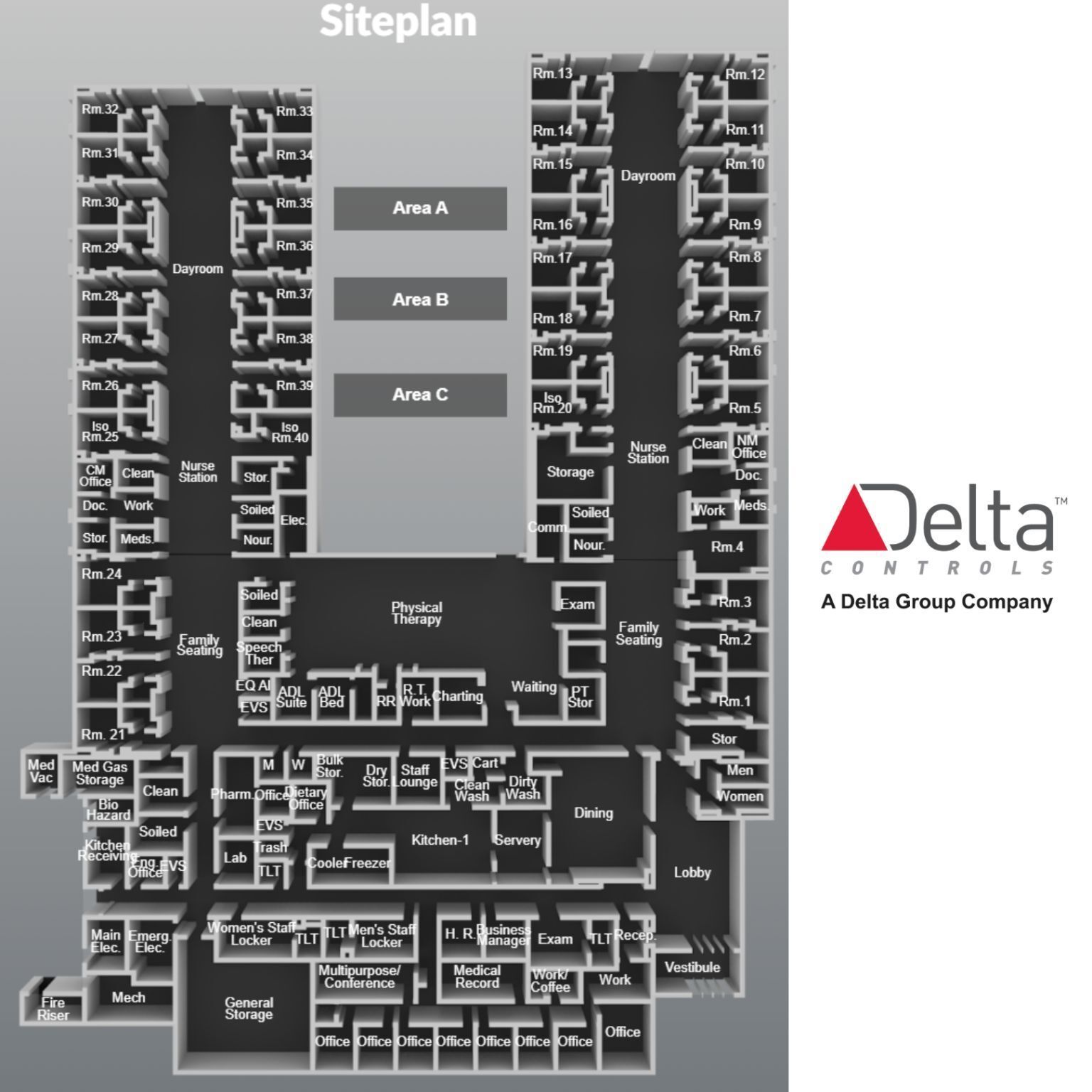

While occupant comfort and safety matter in every HVAC installation, they are essential in health care facilities. HVAC design for health care presents a number of special challenges. Air changes and pressurization between departments must be maintained to avoid cross-contamination. There are strict requirements for ventilation and filtration to prevent the transmission of airborne pathogens. Finally, because different areas of a healthcare facility can have widely varying temperature and humidity requirements, there is a need for extremely accurate, localized control of environmental conditions.

In the past, meeting the needs of healthcare facilities has been a difficult task to accomplish with traditional commercial HVAC rooftop units, which were unable to adjust the sequence of operations to fit healthcare requirements. For Nobis, this led to frequent compressor failure and air pressurization issues. They were ready for a change.

Desired Situation

Nobis Rehab came to Applied Climate seeking new HVAC systems for sites in Texas, Florida, and Arizona. The systems needed to be fundamentally consistent across the various Nobis healthcare facilities, but also adaptable to the unique needs of each individual site. Every site’s systems had to provide excellent indoor air quality through the use of enhanced filtration and UV lights and offer efficient methods for airflow monitoring and humidification.

To ensure ease of management as well as outstanding environmental controls, Nobis Rehab needed a sophisticated building automation system that would tie all these components together with a simple user interface that the building operator could use easily.

Solution Provided by Applied Climate

Consistency is vital when working on nationwide projects that involve furnishing HVAC equipment for multiple locations. Applied Climate met this goal by providing the same equipment solution, startup, and commissioning at all the Nobis Rehab sites it worked on. However, each site also had specific needs, so the team took a hands-on approach to learn the particular requirements and constraints of the site in order to customize the design and installation as needed.

Applied Climate’s hands-on approach frequently shaves months off construction schedules, allowing clients to begin turning a profit more quickly. For Nobis Rehab, the hands-on, customized approach enabled the client to save money on first cost and on operating costs – a total win-win.

The Applied Climate team developed a complete mechanical equipment package for Nobis Rehab that consisted of rooftop units and make-up air units to replace air removed through the kitchen hood’s exhaust system, along with exhaust fans, humidifiers, variable refrigerant flow, unit heaters, and a variable air volume (VAV) system.

To implement the design and respond to the specific needs of the Nobis Rehab sites, the Applied Climate team worked with Dunham-Bush, a top manufacturer of HVAC equipment, to build a custom packaged rooftop unit (RTU) system.

Because traditional HVAC manufacturers only allow a few components in their RTU's, final filters typically must be located in a very tall final filter curb and the humidifier grid must be part of the ductwork. Instead, Applied Climate Solutions designed a system that moved all required components to the RTU. This eliminated the risk of leaks within the building and reduced the RTU height by six feet, improving maintenance accessibility. This innovative new design also provided cost savings to the client because it decreased screen wall height by six feet, reducing the first cost of the facility.

In addition, Applied Climate installed a building automation system that linked all of the equipment together. The operational controls improved efficiency while meeting the engineer’s design specifications. The holistic integration of hardware and controls gives Nobis Rehab complete control over building temperature and indoor air quality, ensuring a comfortable, sterile, and healing environment for patients, staff, and visitors. The operational controls are also essential for Nobis Rehab’s compliance with health care code requirements, which includes daily reporting on interior climate conditions and trends in order to maintain its state healthcare license and continue to serve patients.

Another unique and important feature offered by Dunham Bush is remote access directly into the RTU controller. This gives Applied Climate Solutions and its servicing contractors the ability to diagnose unit operations remotely, greatly increasing speed of response and often avoiding the need to send a service truck to the site. This saves Nobis Rehab money on maintenance and ongoing operations.

Every member of the Applied Climate team, from the project and account managers to area service agents and controls team, maintained a steadfast commitment to a hands-on, client-centered approach throughout the project. This commitment allowed Applied Climate to use its expertise to provide Nobis Rehab with the highest quality products and service from start to finish.

Applied Climate’s hands-on involvement will continue throughout the first year of operation to support the client as they adjust to the new equipment. This extended term of service will give Nobis Rehab staff peace of mind and the freedom to focus on caring for their patients.